RONA BEARING, experience and quality you can trust, meet and exceed your needs.

RONA Bearings produce and supply Deep Groove/ Angular/ Pillow Block / Thrust / Insert Ball Bearings,and Spherical/Cylindrical /Tapered Roller Bearings. Bearings OEM service according to your requirement.RONA BEARING, stock kinds of worldwide brands bearings for fast delivery.

RONA Bearings produce and supply Deep Groove/ Angular/ Pillow Block / Thrust / Insert Ball Bearings,and Spherical/Cylindrical /Tapered Roller Bearings. Bearings OEM service according to your requirement.RONA BEARING, 30 years industrial bearings and parts manufacturer from China.

RONA Bearings produce and supply Deep Groove/ Angular/ Pillow Block / Thrust / Insert Ball Bearings,and Spherical/Cylindrical /Tapered Roller Bearings. Bearings OEM service according to your requirement.RONAB EARING, enjoy popularity in America, Southeast Asia, Africa, Middle East markets etc.

RONA Bearings produce and supply Deep Groove/ Angular/ Pillow Block / Thrust / Insert Ball Bearings,and Spherical/Cylindrical /Tapered Roller Bearings. Bearings OEM service according to your requirement.PRODUCTS

Quality first, Technology leading, Iso certified,Transportation specialized.

-- Shanghai Rona Bearing Co., Ltd.Bearings Applications

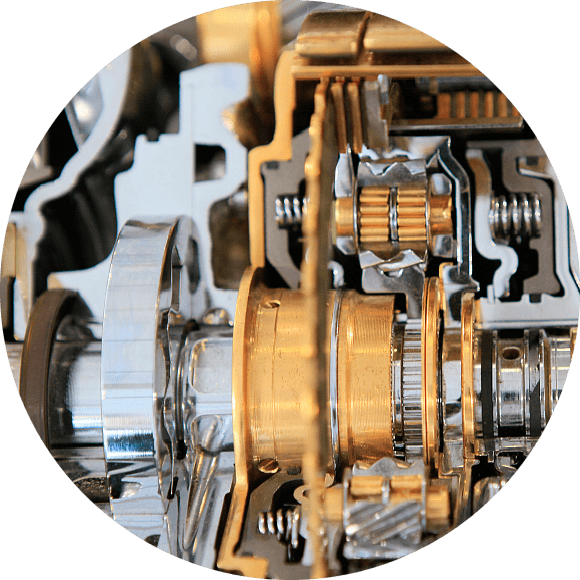

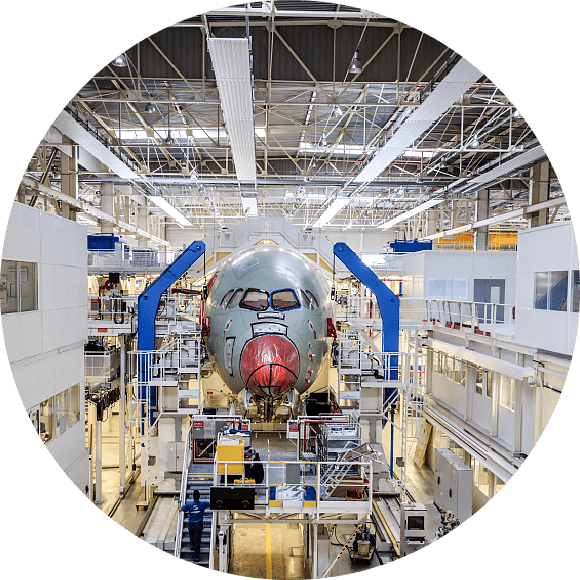

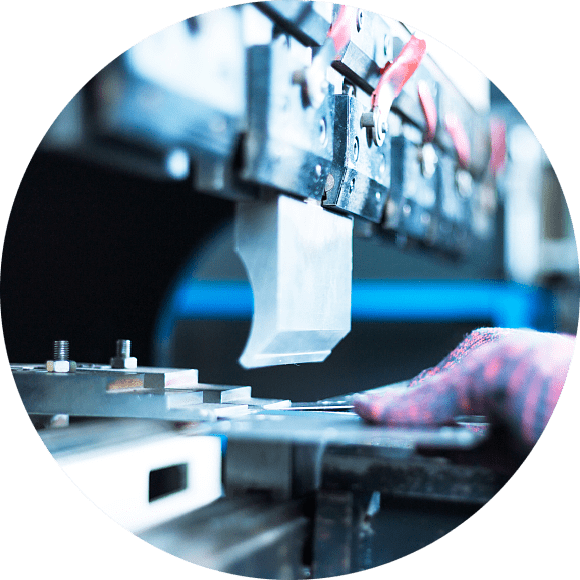

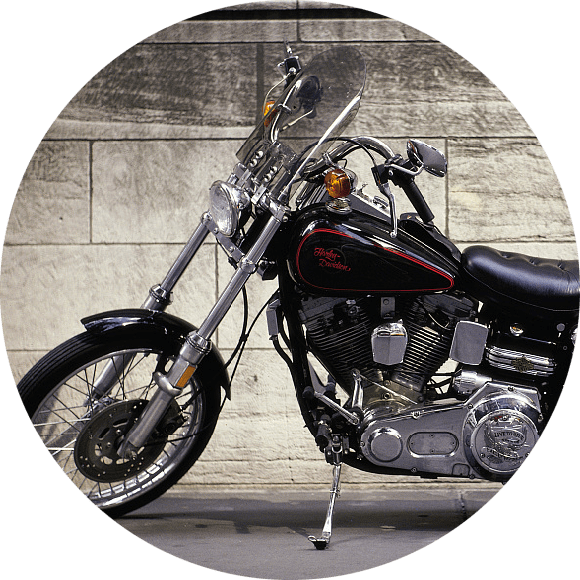

RONA Bearings are widely used in various of industries, and will bring more reference value for global customers.

About Us

Shanghai Rona Bearing Co., Ltd., was established in 1998, engaged in manufacturing bearings and power transmission. We have a wide variety of bearings in huge stocks: deep groove ball bearings, cylindrical roller bearings, tapered roller bearings, self-aligning ball bearings, angular contact ball bearings, thrust ball bearings, thrust roller bearings, pillow block bearings, needle roller bearings, joint bearings, high-temperature resistant bearings, stainless bearings, ceramic bearings, stamping bearings, miniature bearings, rolling mill bearings, slide bearings, water pump bearings, non-standard bearings etc. With our professional factory stringent quality and martials supply control standards, OEM and ODM service supported. To support our bearings export to many countries and regions all over the world, in 2013, we set up the Russia & Hongkong offices for services.

RONA INDUSTRIAL CO., LTD., was set up in 2014 in Hongkong, which is an International trading group to supply our customers with perfect products and professional services to the foreign markets. we have well famous bearings like SKF, FAG, NTN, INA, NSK, NACHI, KOYO, IKO and China bearings HRB, ZWZ, LYC, etc., We have extensive cooperation with countries in East and South Asia, Europe, and the Americas, including Russia, Ukraine, Brazil, Kazakhstan, Uzbekistan, Spain, Mexico, India, Korea, UK, UAE, Turkey, Vietnam, Italy and other industrial areas.

RONA Bearing will work very hard to build lasting relationships with you and will be quite proud to be your loyal partner to assist you gain more and more profits & reputation with our best bearings and best service!

CONTACT

RONA appreciates the support from all customers and its teams and partners. We look forward to long-term win-win cooperation with you!

© 2021 Shanghai Rona Bearing Co., Ltd.